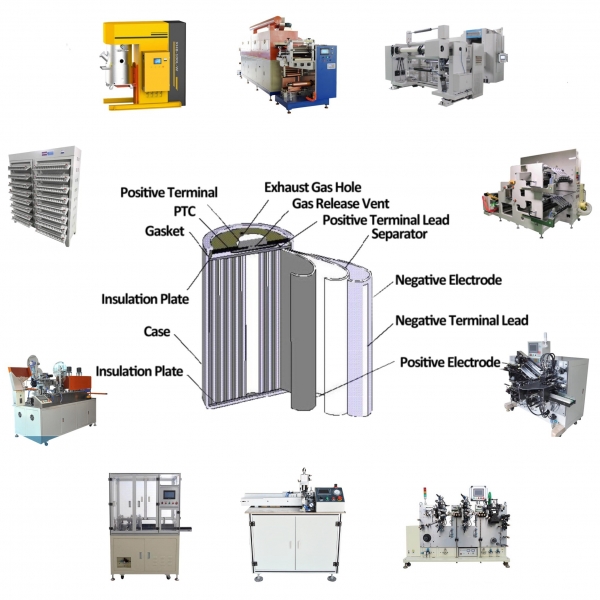

Linea di macchine per la produzione di celle cilindriche automatiche

fabbricazione e attrezzatura del laboratorio della batteria agli ioni di litio 18650

diagramma di flusso delle celle a bottone agli ioni di litio ed elenco delle macchine

fabbricazione e attrezzatura del laboratorio della batteria del sacchetto dello Li-ione

- Posta elettronica : David@tmaxcn.com

- Posta elettronica : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

A cell production line is a highly specialized and automated system designed to manufacture individual battery cells, which are the building blocks of batteries used in electric vehicles (EVs), consumer electronics, renewable energy storage, and other applications. These lines integrate various processes and machines to handle the delicate materials and complex steps involved in cell manufacturing.

In this article, we will explore the components, functionalities, advantages, challenges, and innovations driving the evolution of cell production lines.

●Components of a Cell Production Line

A typical cell production line consists of several stages, each requiring specific machinery and tools:

1. Material Preparation

Function: Prepares raw materials such as active materials, binders, conductive additives, and current collectors.

Key Machines:

Mixing machines for slurries or powders.

Dispensing systems for precise material application.

2. Coating and Drying

Function: Applies active material slurries onto current collector foils (aluminum for cathodes, copper for anodes) and dries them to form electrodes.

Key Machines:

Slotdie coating machines.

Controlled drying ovens with temperature and humidity regulation.

3. Calendering

Function: Compacts coated electrodes to achieve desired density and porosity.

Key Machines:

Rolltoroll calendering systems.

4. Cutting and Slitting

Function: Cuts or slits coated electrodes into precise dimensions for cell assembly.

Key Machines:

Laser cutting machines.

Precision slitting systems.

5. Stacking/Winding

Function: Assembles electrodes and separators into stacked or wound configurations.

Key Machines:

Stacking machines for prismatic and pouch cells.

Winding machines for cylindrical cells.

6. Cell Assembly

Function: Integrates electrodes, separators, electrolytes, and casing into complete battery cells.

Key Machines:

Electrode insertion systems.

Sealing and welding equipment.

7. Electrolyte Filling

Function: Injects electrolytes into assembled cells under controlled conditions.

Key Machines:

Vacuum filling systems.

Pressure control units.

8. Formation and Aging

Function: Activates and stabilizes battery cells through controlled charging and discharging cycles.

Key Machines:

Formation chambers with temperature control.

Aging racks for longterm stability testing.

9. Testing and Sorting

Function: Evaluates cell performance and sorts them based on capacity, internal resistance, and other parameters.

Key Machines:

Testing stations with advanced sensors.

Automated sorting systems.

●Functionalities of a Cell Production Line

1. Automation:

Reduces human intervention, minimizes errors, and increases throughput.

2. Precision Control:

Ensures uniformity in thickness, density, alignment, and other critical parameters.

3. RealTime Monitoring:

Continuously measures and adjusts key variables such as temperature, pressure, and speed.

4. Scalability:

Adaptable to different battery chemistries, sizes, and form factors (cylindrical, prismatic, pouch).

5. Integration:

Connects all stages of production into a seamless workflow, optimizing efficiency.

1. High Throughput:

Enables mass production of battery cells with consistent quality.

2. Cost Efficiency:

Minimizes labor costs and material waste through automation.

3. Improved Performance:

Ensures optimal electrode density, porosity, and alignment for better battery performance.

4. Environmental Benefits:

Dry electrode processes reduce solvent use, lowering emissions and waste.

5. Customization:

Can be tailored to handle specific materials and chemistries, including nextgeneration technologies like solidstate batteries.

●Challenges in Cell Production Lines

1. Complex Material Handling:

Delicate materials like solidstate electrolytes require specialized handling to avoid damage.

2. Uniformity Control:

Achieving consistent thickness, density, and alignment across large batches is challenging.

3. Binder Selection:

Developing binders that work effectively in dry conditions while maintaining adhesion is complex.

4. High Initial Costs:

Advanced machinery and specialized components come with significant upfront investment.

5. Process Optimization:

Finetuning parameters such as temperature, pressure, and speed is essential for achieving consistent results.

●Innovations in Cell Production Lines

To address these challenges and enhance productivity, manufacturers are incorporating cuttingedge technologies:

1. AI and Machine Learning:

Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

2. RealTime Monitoring Systems:

Integrated sensors and vision systems provide continuous feedback on critical parameters.

3. Modular Design:

Flexible systems allow for easy reconfiguration to test new materials and chemistries.

4. Sustainability Features:

Ecofriendly practices and recycling capabilities minimize waste and energy consumption.

5. Integration with Automation:

Collaborative robots (cobots) and IoTenabled systems enhance efficiency and reduce human intervention.

●Applications of Cell Production Lines

Cell production lines are used in various industries, including:

1. Electric Vehicles (EVs):

Produces highcapacity, longlife cells for EVs.

2. Consumer Electronics:

Manufactures compact and efficient cells for smartphones, wearables, and portable devices.

3. Renewable Energy:

Develops durable cells for gridscale energy storage systems.

4. Industrial Applications:

Creates highperformance cells for heavyduty applications like trucks, buses, and construction equipment.

●The Future of Cell Production Lines

As the demand for sustainable and highperformance energy storage solutions grows, cell production lines will continue to evolve. Key trends shaping the future include:

1. Increased Automation:

Fully autonomous systems will further boost production speeds and reduce costs.

2. Customization Options:

Modular designs will enable manufacturers to tailor systems for specific materials and cell designs.

3. Focus on Sustainability:

Ecofriendly practices and recycling capabilities will become integral parts of future systems.

4. Integration with Emerging Technologies:

Solidstate batteries, flexible electronics, and autonomous systems will drive new innovations in system design.

5. Smart Manufacturing:

IoTenabled systems will leverage big data and AI to optimize production, reduce waste, and enhance efficiency.

●Conclusion

Cell production lines are the backbone of modern battery manufacturing, enabling the development of highperformance, costeffective, and sustainable battery cells. Their ability to handle diverse materials, optimize processes, and scale production makes them indispensable for meeting the growing global demand for energy storage solutions.

What excites you most about the role of cell production lines in driving innovation and sustainability in the energy storage sector? Share your thoughts below! Together, let’s explore how this technology can shape the future of energy storage.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com