- pilota batteria / linea di produzione

- gruppo laboratorio batteria

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Materiali per batterie agli ioni di litio

- materiali catodici attivi

- materiali anodi attivi

- Customized Battery Electrode

- Materiali della pila delle monete

- chip di litio

- parti di celle cilindriche

- collettori di corrente della batteria

- materiali conduttivi della batteria

- elettrolita e custodia

- Metal Mesh

- legante della batteria

- separatore e nastro

- film laminato di alluminio

- striscia / lamina di nichel

- Battery Tabs

- materiali di grafene

- Nickel Felt

- Titanium Fiber Felt

- Batteria

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- tutte le macchine per l'assemblaggio delle batterie

- tester e analizzatore di batterie

- Battery Safety Tester

- Material Characterization Tester

- macchina rotativa

- saldatrice a punti di metallo

- macchina del miscelatore di vuoto

- aggraffatura / smontaggio macchina

- macchina sottovuoto

- riempimento di elettroliti

- impilatore / avvolgitore

- taglierina / taglierina dell'elettrodo

- macchina formatrice di sacchetti

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vuoto scatola per guanti

- forni

- Coaters

- PVD Coater

- pressa idraulica

- Large Press Machine

- miscelatore centrifugo planetario / mulino

- Mulino a sfere

- macchina da laboratorio

- Forni a vuoto

- camera di prova di umidità di temperatura

- Hardness Tester

- Spray Dryer

- Cutting Machine

- incubatrice

- evaporatori rotanti

- Viscometer

- Three Roller Mill

- analizzatore di superficie

- frantoio da laboratorio

- macchina di polimerizzazione UV

- congelatori ultra bassi

- Water Chiller

- Laser Cleaning Machine

- altre apparecchiature di laboratorio

- Cutting Machine

- schiuma di elettrodi metallici

- WhatsApp : +86 18659217588

- Posta elettronica : David@tmaxcn.com

- Posta elettronica : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

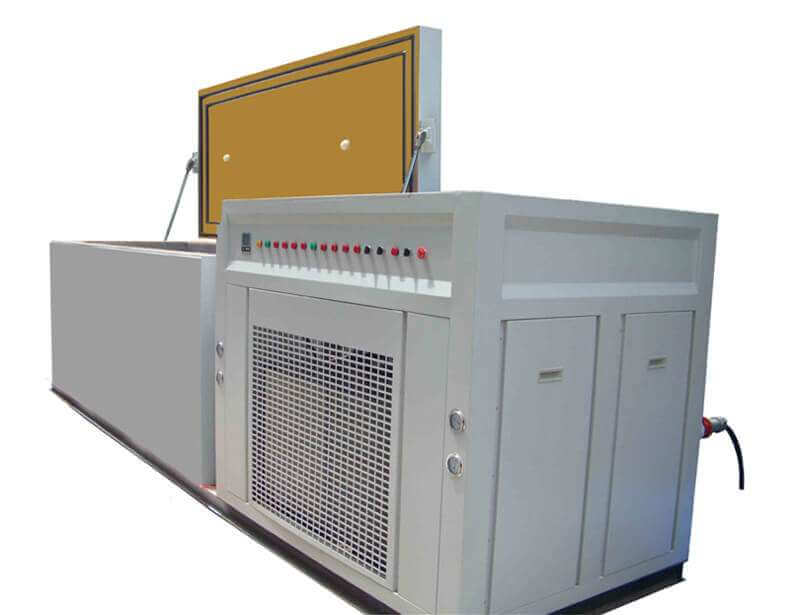

Grande frigorifero industriale a bassissima temperatura

Model Number:

TMAX-B60MOQ:

1Pagamento:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Posta elettronica : David@tmaxcn.com

- Posta elettronica : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Precedente:

Lab -180 ℃ Congelatore a temperatura ultrabassaProssimo:

Congelatore a pozzetto ultra basso da laboratorio -180 ℃

Large Industrial Ultra-low Temperature Refrigerator

Applications

1. It is mainly used to assess and determine the adaptability test of parts and materials of electrical, electronic, aerospace, automobile electrical appliances, materials and other products, electronic components and other related products when they are stored and used in low temperature and constant temperature environment, and test their performance indexes.

2. It is mainly used in the industrial cooling treatment to make the homogeneous, fine and dispersive carbonization products on the metal structure matrix precipitate. The precipitation of this kind of carbide will improve the wear resistance and friction performance of the metal significantly, the hardness will also increase, and will directly improve the life of the wear parts. An ideal alternative to liquid nitrogen.

3. It is used for copper sleeve, bearing and other cold shrinkage, widely used in precision machinery assembly.

4. It is applied to the ultra-low temperature test of large equipment (automobile, large construction machinery, aircraft parts, aerospace equipment parts, military equipment parts).

5. Food preservation and refrigeration;

6. Cold storage of seafood;

7. Can be used as low temperature refrigeration equipment of cold chain logistics distribution vehicle

Features

● Easy to use: the refrigerator door adopts full-automatic valve control, and the door opening and closing are completely controlled by electricity, which is easy and convenient.

● Safety: the panel control is equipped with 4 fault lights, such as valve switch, refrigeration switch, operation and fault. If any part fails, the fault light will be on, and the unit will automatically protect and stop operation without any danger.

● Energy saving: save energy consumption through special compressor system and refrigerator door system, users can use it at ease.

● microcomputer control, cascade temperature controller, digital display of temperature, adjustable unit 0.1 degree, temperature range in the box - 20 degrees to - 125 degrees;

● multiple safety protection, more reliable operation;

● French Taikang compressor, German blog compressor, bizel compressor, binary cascade supercooling technology;

● it has self diagnosis function, refrigerator overload protection, high pressure switch, overload relay, thermal protection device and other safety protection functions to fully ensure the use safety;

Three layer sealing, mold heat breaking layer, super thick polyurethane foam insulation layer, better insulation; embedded vacuum insulation board.

● humanized design, flexible and convenient;

● it is suitable for the environment of mechanical workshop;

● super large condensation design to ensure the cooling effect of workshop environment;

● large volume ratio design; large capacity bearing capacity design;

● it can set the temperature difference between the compressor on and off;

● various fault alarms (overtemperature alarm, sensor alarm, high pressure alarm, compressor overtemperature alarm;

● startup delay protection;

● all parts are grounded safely;

● LED display, which can display the temperature in the box and the set temperature at a glance; it can set the over temperature alarm and the temperature in the box, with the function of fault prompt;

Customized non-standard size, ultra-low temperature freezer (can produce and manufacture ultra-low temperature freezer within - 100 degrees and 100 cubic meters)

● optional color touch screen, temperature recorder and other equipment

SPECIFICATIONS

Model |

TMAX-B60-1000L |

TMAX-B60-1500L |

TMAX-B60-2500L |

TMAX-B60-3500L |

Volume |

1020L |

1700L |

2500L |

3400L |

temperature range |

-40~-60℃ |

-40~-60℃ |

-40~-60℃ |

-40~-60℃ |

carrying capacity |

500KG |

500KG |

500KG |

500KG |

Cooling mode |

Air cooling |

Air cooling |

Air cooling |

Air cooling or water cooling |

Refrigerant injection |

R404A+R23 |

R404A+R23 |

R404A+R23 |

R404A+R23 |

Chamber size (Width * depth * height) |

1000*600*1700 |

1000*1000*1700 |

1000*1500*1700 |

1000*2000*1700 |

Overall size (Width * depth * height) |

1500*1800*2200 |

1500*2200*2200 |

1500*2700*2200 |

1500*3200*2200 |

Door opening mode |

Heavy hinged door, heavy stainless steel door lock |

|||

Temperature control |

PID temperature control, temperature control accuracy ± 0.1 ℃ |

|||

sensor |

PT100 platinum resistance, ± 100 ℃ |

|||

Indicator light |

Indicator light: power failure light, compressor running light, compressor failure light, fan failure light |

|||

Safeguard |

Protection: leakage proof air switch, high and low voltage, overvoltage and undervoltage, phase loss, overcurrent, double door seal |

|||

Power Supply |

Three phase five wire 380V 50Hz |

|||

Various specifications and models can be customized according to customers' needs: |

||||

1 |

Loading capacity; |

|||

2 |

Chamber size: length, width, height or overall dimension of parts provided; |

|||

3 |

Time to cool down to the target value under full load. |

|||

Related small freezer

Model |

Internal dimensions (L*W*H, mm) |

External dimensions (L*W*H, mm) |

Power |

Temperature range |

Product features |

TMAX-40-50-LA |

360*408*405 |

540*630*1080 |

315 |

-15℃~-40℃ |

Top opening door, with secondary insulation door inside, right angle flat bottom or with step liner, imported microcomputer temperature controller, with sound and light alarm system |

TMAX-40-158-LA |

460*430*800 |

700*700*1535 |

550 |

||

TMAX-40-60-WA |

390*370*400 |

520*500*795 |

300 |

||

TMAX-40-100-WA |

695*465*300 |

900*670*795 |

350 |

||

TMAX-40-200-WA |

845*465*590 |

1050*670*795 |

400 |

||

TMAX-40-300-WA |

1195*465*590 |

1400*670*795 |

450 |

||

TMAX-40-568-WA |

1755*465*650 |

1880*670*795 |

550 |

||

TMAX-40-1000-WA |

2120*757*670 |

2265*898*843 |

900 |

||

TMAX-60-50-LA |

360*408*405 |

540*620*1080 |

400 |

-25℃~-65℃ |

Integral polyurethane foam door, stainless steel insulated inner door, imported microcomputer temperature controller, complete alarm system |

TMAX-60-158-LA |

460*430*800 |

540*620*1080 |

600 |

||

TMAX-60-400-LA |

550*630*1140 |

700*700*1535 |

800 |

||

TMAX-60-598-LA |

700*680*1255 |

850*930*1945 |

1200 |

||

TMAX-60-60-WA |

390*370*400 |

940*950*1920 |

350 |

||

TMAX-60-108-WA |

695*465*300 |

520*500*795 |

400 |

||

TMAX-60-208-WA |

845*465*590 |

900*670*795 |

450 |

||

TMAX-60-308-WA |

1195*465*590 |

1050*670*795 |

500 |

||

TMAX-60-468-WA |

1260*540*670 |

1400*670*795 |

600 |

||

TMAX-86-50-LA |

360*408*405 |

540*630*1080 |

400 |

-40℃~-86℃ |

|

TMAX-86-158-LA |

460*430*800 |

700*700*1535 |

720 |

||

TMAX-86-400-LA |

550*630*1140 |

850*930*1945 |

850 |

||

TMAX-86-598-LA |

700*680*1255 |

940*950*1920 |

1300 |

||

TMAX-86-60-WA |

390*370*400 |

520*500*795 |

400 |

||

TMAX-86-108-WA |

695*465*300 |

900*670*795 |

400 |

||

TMAX-86-120-WA |

550*400*555 |

1280*780*980 |

450 |

||

TMAX-86-208-WA |

845*465*590 |

1050*670*795 |

450 |

||

TMAX-86-308-WA |

1195*465*590 |

1400*670*795 |

500 |

||

TMAX-86-468-WA |

1260*540*670 |

1920*800*1070 |

700 |

||

TMAX-136-120-WA |

550*400*545 |

1280*780*980 |

2300 |

-80℃~-136℃ |

|

TMAX-153-120-WA |

550*400*545 |

1280*780*980 |

3800 |

-110℃~-153℃ |

|

TMAX-165-120-WA |

550*400*545 |

1280*780*980 |

4800 |

-120℃~-165℃ |

|

TMAX-180-120-WA |

550*400*545 |

1280*780*980 |

8500 |

-140℃~-180℃ |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com